Kyoto is the traditional industrial and textile hub of Japan. Here, most of Japan's kimonos and obis are woven, dyed and embroidered. In Kyoto, you can see kimonos as part of daily life, as a fashion statement and as an extricable part of the culture, from the performing arts to the myriad ceremonies to local customs. When we visited this city last, we were able to experience the tradition of Kyoto Yuzen or Kyo-Yuzen.

Kyo-Yuzen is applied in two styles: Tegaki Yuzen (hand-painted yuzen) and Kata Yuzen (stencil-dyed yuzen). A fan painter in Kyoto named Yuzensai Miyazaki invented the yuzen hand-painted techniques in the Edo period around 1700. With the popularity of his fans, he began to receive commissions from aristocrats to paint kimono fabrics. Yuzensai Miyazaki developed the process to create high quality, dyed fabric whose art would not be ruined by rain, humidity, sweat, sunlight and so on, yet retained the artistic and nuanced qualities of hand painted artwork. Painted yuzen uses a rice-paste resist (a barrier that blocks certain parts of the cloth from being dyed). Learn more about Tokyo Hand-Painted Yuzen.

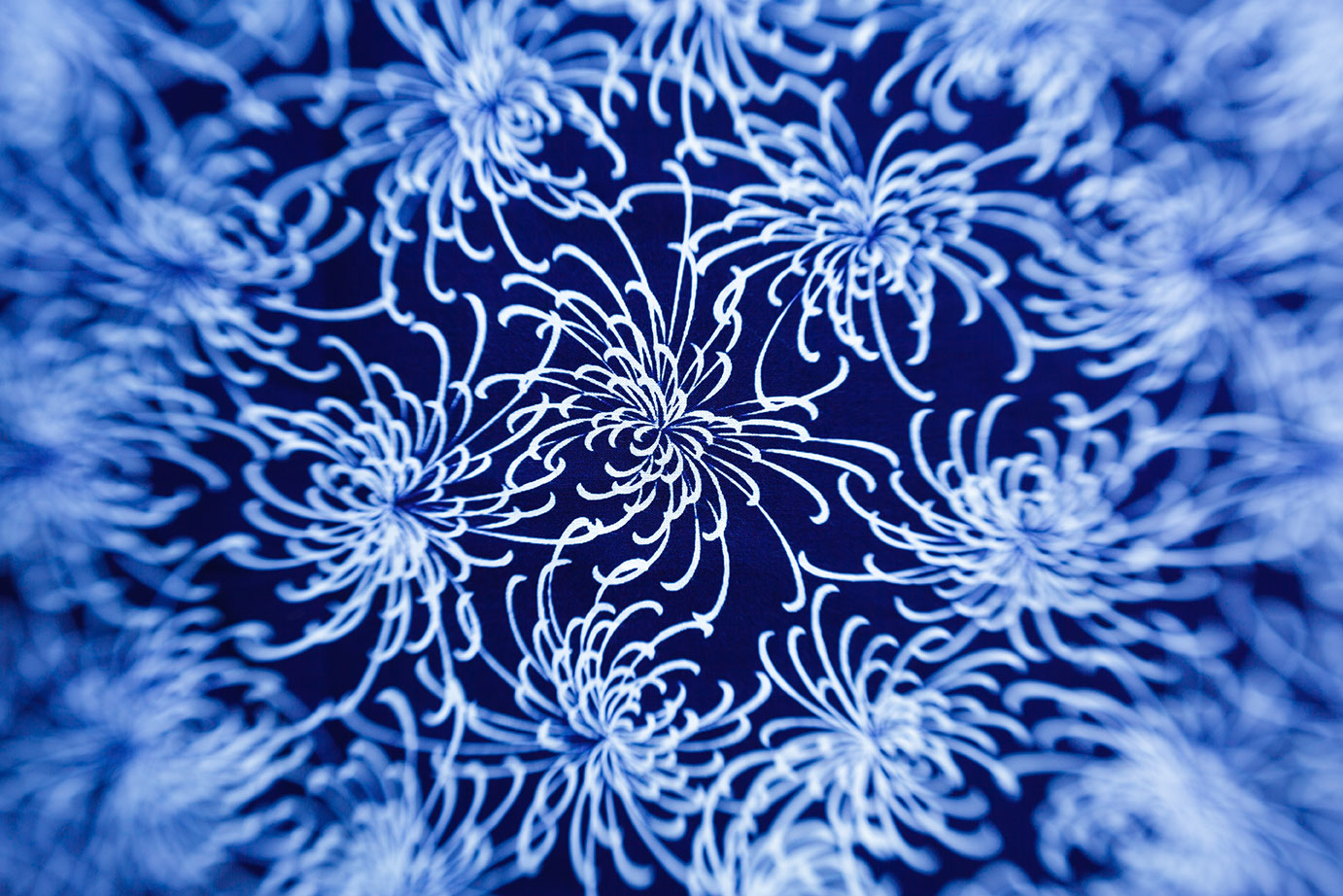

Katazome or stencil dyeing is a dyeing method that uses a stencil to create repeated patterns, either using dye paste or a resist paste. The stencil is usually made of a stiff type of paper infused with persimmon juice, and is washed and reused until it falls apart. Edo Komon and Kata Yuzen are types of Katazome stencil dyeing methods. Kata Yuzen techniques were developed by Jisuke Hirose in Kyoto around 1880. With combinations of stencil, brush and resist techniques, the dye craftsmen created fabric that is its own art form. The characteristic point of Kyo-Yuzen dyeing is to dye complicated patterns with many colors and tonal gradation. And, of course with the dyeing process, fabric can be produced in larger quantity than by just hand painting.

After the fabric is dyed it is dried, steamed, washed and dried. The steaming process sets the yuzen dye. Without this labor-intensive process, the product cannot be called yuzen. The color transmission is incredible, resulting in fabrics with impressive and deep colors. The fabric below shows one of our Yuzen kimono patterns - the Indigo Kiku - made into a pocket square.

In some ways, kimonos are a centuries-old version of ethical luxury. You can wear them for decades, even if your body shape changes. When they become used, you can make them into a futon, cushion or any creative application. They cycle through seasons, not trends. In that regard alone, the price-performance of kimonos is actually quite high.

Author: Aruña Quiroga